Little shop project I did. Posted several threads about RAM mounts some in newer and older tractors. https://talk.newagtalk.com/forums/thread-view.asp?tid=798447 Thanks to AGB for the emailed pictures and some very good ideas. https://talk.newagtalk.com/forums/thread-view.asp?tid=799850 And a shout out to Little Duck for the design idea using the window latch cab boss mounts. https://talk.newagtalk.com/forums/thread-view.asp?tid=453478&mid=#M3681518 After various threads with ideas and suggestion for mounting RAM mounts in the older Sound Gard Cabs I decided to try making my own.

Not sure this would stand up to the heavier load of a monitor or I-pad but should be sufficient for just a simple phone mount.

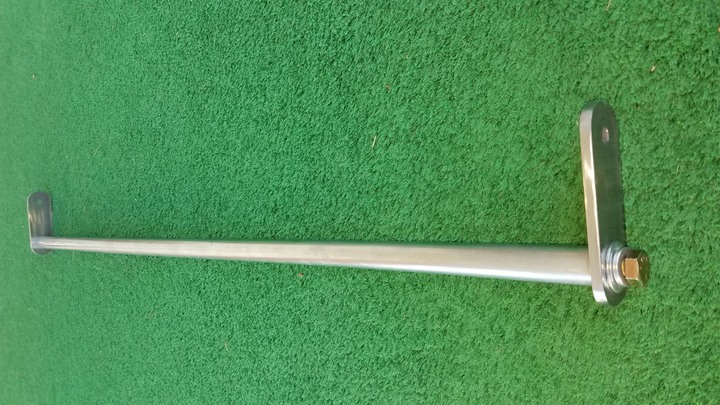

It utilizes mostly friction and tension to hold the ear tabs against the 1/4'" threaded boss on the posts that the window slide lever works on.

I wanted to put the tab against the boss and then reinstall the lever and hardware. However when attempting this it put a lot of side load on the window lever and I thought forcing the window lever to the locked position might eventually break the window glass. I used a Phillips bit in a 1/4" battery impact driver to remove the Phillips head machine screws. It removed them quickly with no problem. I used a couple short pieces of 3/16" x 1-1/4" flat steel for the mounting ears.

A 1/4" hole was drilled approx. 3/4" in from one end.

A 3/8" hole was drilled approx. 3" in from the 1/4" hole.

The pieces were cut off and bolted together.

I used some fender washers for a pattern to get the rounded ends and ground them to the profile I wanted

I had a short piece of 1/2" EMT metal conduit which I thought would be strong enough for a phone mount without being a lot of weight.

I also had a couple of these Hillman threaded rod couplers that I had intended on welding into the end of the conduit.

Turns out they were a tight enough fit to drive into the conduit without distorting it.

The extra length will help support more of the conduit tube and it came in handy as I actually needed to drive one in a little further and grind the conduit down flush since the over all length needed to be a bit shorter than the measured distance. Probably due to bosses and cab posts not being perfectly plumb and square.

Sanded all the pieces and primed and painted with black paint.

At first I used 3/8" bolts with washers to attach the tube to the ears.

However that interfered with the over center latches working.

I used a couple flat machine screws with a screwdriver slot in the head which gave more clearance.

I seldom open the side glasses anyhow and while the flat head machine screws help some they still do not allow the latches to go into the detent position that hold the window open.

The window still opens a fair amount but just does not go into the detent position to be held open.

I suppose adjusting with washers or shims would allow the latches to be fully functional but that also moves the ears farther off the threaded boss in the post and with only a 1/4" bolt to hold it tight might be asking a bit much. Had these bosses been tapped for a 5/16" or 3/8" bolt that might be more feasible.

I've got a mount like this on the way for clamping to the rail.

Dimensions check out that it should draw tight down on the tube. If there is enough clearance between tube and window I might be able to rotate the ears so they hang straight down instead of facing 90°out away from the posts. Just my thoughts on how to do a RAM mount rail for a lighter device like a phone.

Certainly less money than the aftermarket one that was over $100 and even if this does not work as expected I am not out much and can use a suction cup mount instead.

Hope others find the idea useful or helpful for their own needs. |

Made a JD Sound Gard RAM mount bar (pic warning)

Made a JD Sound Gard RAM mount bar (pic warning)